Cutting Phase

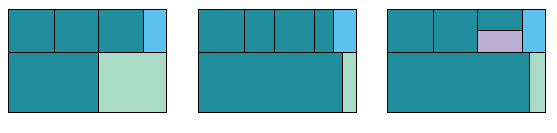

A sequence of guillotine cuts (from one side of the plate to the other) in the same direction – horizontally or vertically – makes up a cutting phase, eventually also called the cutting stage. Thus, when requesting a two-phase cutting plan, it is expected to rotate only once (2nd phase) the strips produced in the first cutting phase.

Two-phase cuts can be:

- Exact – in which all parts of the same strip have the same width. The first advantage of this type of plan is the time gain with the minimization of equipment handling for adjustments to different widths of the strip to be cut. Another advantage is that its calculation naturally ends up bringing together, on the same plates, parts of the same dimensions, facilitating their stock or finishing process after cutting.

- Inaccurate – parts of the same strip can have different widths.

The cuts in 3 phases are also called Z Cuts. phase are named Cortes W.

Using cutting plans with more or less phases can be a technical definition or a strategic decision. If it’s a technical definition, there’s usually nothing to do. For one-dimensional cuts, of the slitter type, for example, the plane will naturally have to be a single phase. Automatic sectioners also usually restrict the number of phases and, therefore, there is no way to configure the free option in Corte Certo.

Strategic decisions involve the question: which is more expensive for this company, the raw material or the cutting process as a whole (energy, machine use, hand time work, etc.). Two-stage cutting planes, for example, usually speed up the cutting process a lot, but the raw material yield is rarely excellent.